Dealer Management System – Spares Management

In the fast-paced automotive industry, where every second counts, having the right spare parts at the right time can make all the difference between seamless service and costly downtime.

A spares management solution is a software system that efficiently organizes and oversees spare parts and inventory within the automotive sector. It’s crucial for auto manufacturers, dealerships, repair shops, and related businesses that handle diverse spare parts, ensuring seamless operations and effective customer service through real-time tracking and optimization.

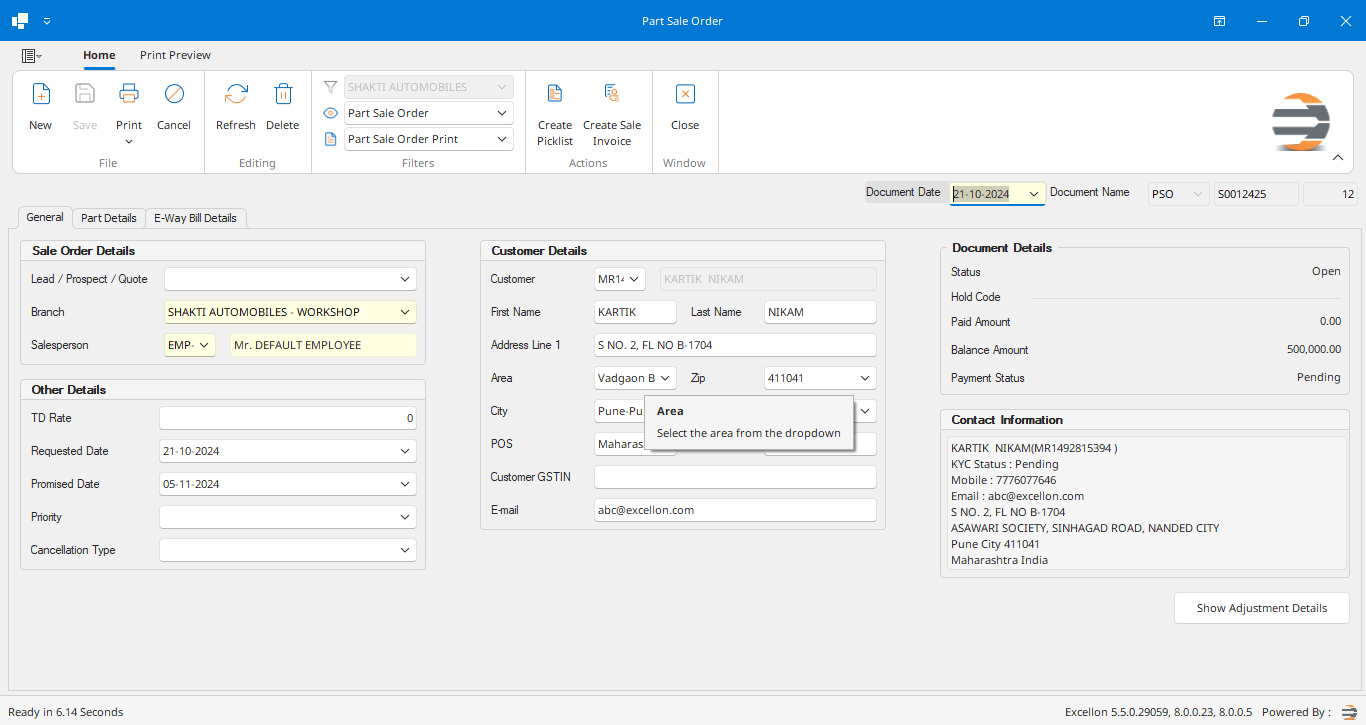

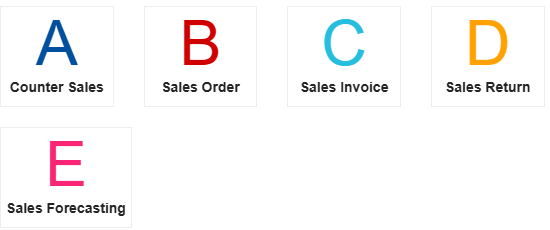

Parts Sale Order and Sales Management

It facilitates placing and managing orders for spare parts. An effective order management system contributes to the overall efficiency and success of the automotive spares management solution by streamlining the order process, tracking statuses, and managing supplier relationships.

Special Features

Features in Detail

- Counter Sales: Streamline the process enabling users to generate a document for the purpose of recording spare parts sold to customers in a single step.

- Sales Order: It is a procedural step that facilitates the creation of bulk part orders for a specific customer based on a raised request, enhancing the efficiency of the overall ordering process.

- Sales Invoice: A crucial element in the transaction process, where the seller provides the buyer with a document containing comprehensive details about the transaction.

- Sales Return: It is the process of authorizing and managing the return of items initially sold to customers.

- Sales Forecasting: This functionality enables users to forecast spare parts sales for a specified defined period, enhancing the overall planning and management process.

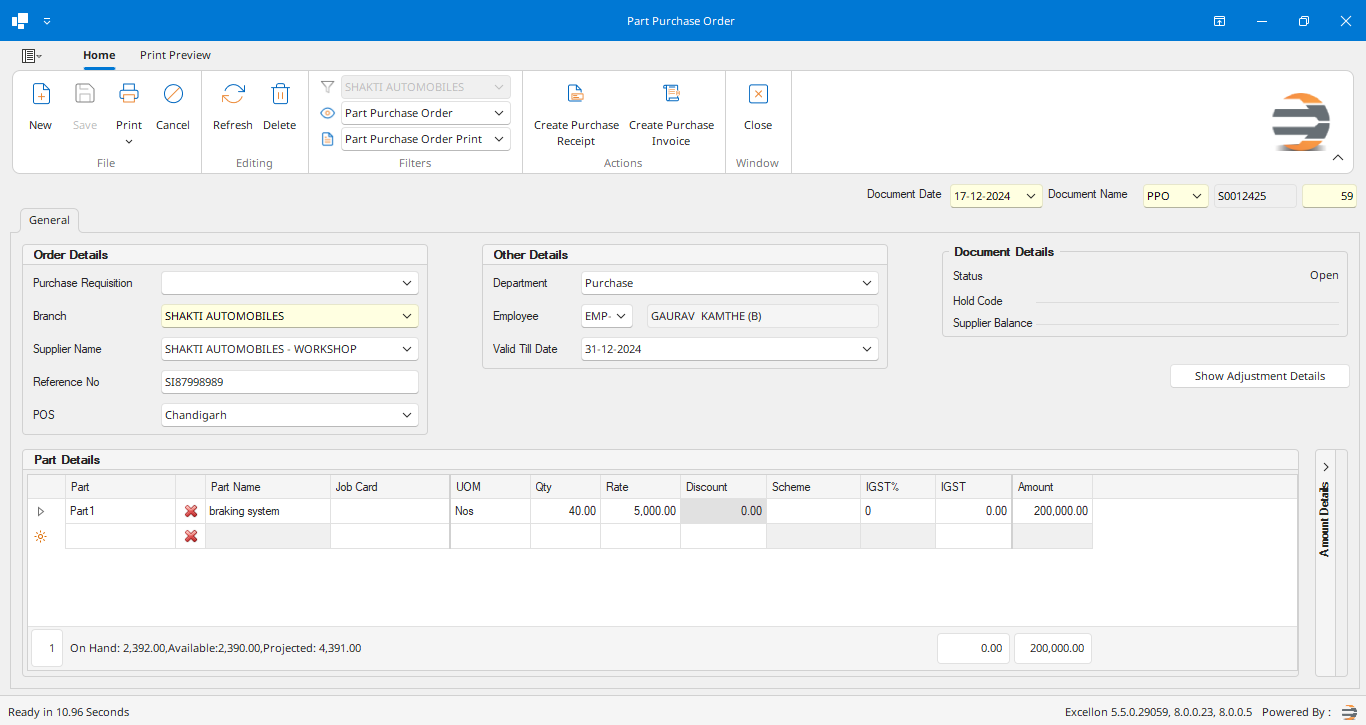

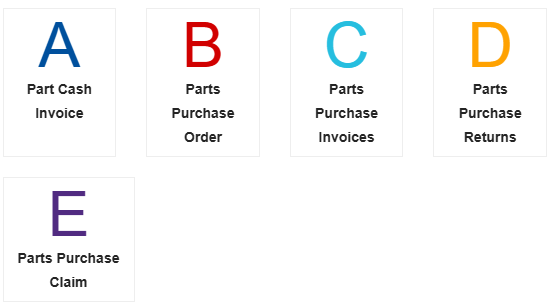

Spares/Parts Purchase Management involves the systematic process of procuring and managing spare parts inventory for various industries. This encompasses creating purchase requisitions, issuing purchase orders, coordinating with suppliers, receiving, and inspecting incoming parts, and updating inventory records. The goal is to ensure timely availability of necessary spare parts, optimize inventory levels, and streamline the overall procurement process to support efficient operations and maintenance.

Special Features

Features in Detail

- Part Cash Invoice: Process that facilitates the inward recording of spare parts purchased from suppliers not utilizing DMS (Dealer Management System), offering flexibility in managing inventory from various sources.

- Parts Purchase Order: The procurement process that involves acquiring spare parts directly from the Original Equipment Manufacturer (OEM), ensuring a direct and streamlined supply chain for necessary components.

- Parts Purchase Invoices: Enable users to record the inward movement of spare parts into inventory, simultaneously triggering accounting entries to ensure accurate financial tracking.

- Parts Purchase Returns: Feature that involves the return of purchased parts directly to the Original Equipment Manufacturer (OEM), ensuring a systematic and efficient mechanism for managing product returns.

- Parts Purchase Claim: It involves claiming damaged or shortage parts received from the Original Equipment Manufacturer (OEM), providing a structured approach to address and rectify issues with the procured components.

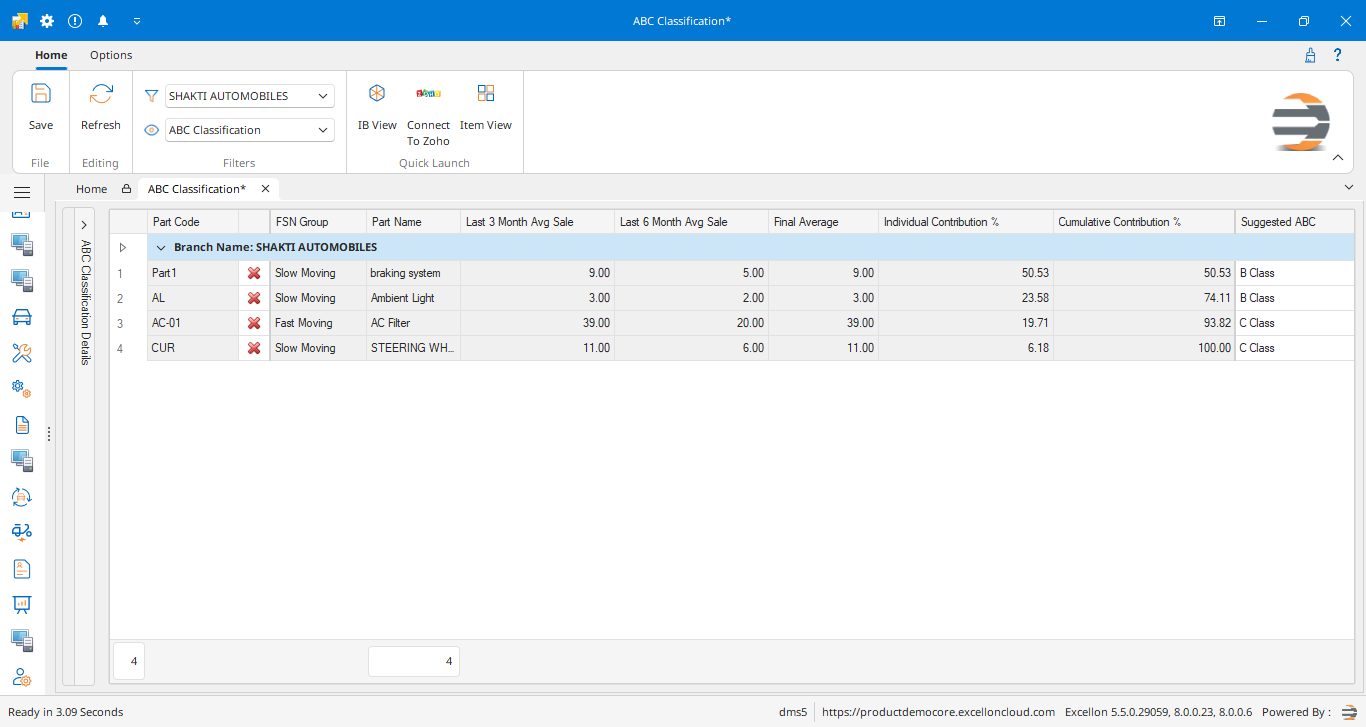

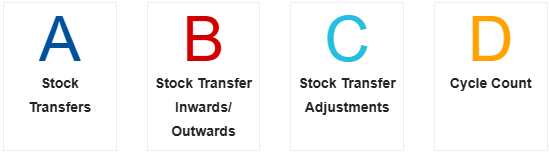

Parts Inventory Management

Systematic control and oversight of spare parts within an organization. It encompasses various processes, including procurement, stock tracking, storage, and distribution, aiming to ensure optimal availability of spare parts for maintenance and repair needs. The key objectives include minimizing stockouts, reducing excess inventory, streamlining procurement processes, and enhancing overall operational efficiency. Effective inventory management of spare parts contributes to cost savings, improved equipment reliability, and streamlined maintenance workflows.

Special Features

Features in Detail

- Stock Transfers: Streamlined process feature for transferring spare parts from one branch to another within the same dealership, ensuring efficient inventory management and optimal utilization of resources.

- Stock Transfer Inwards/ Outwards: Transferring of spare parts from one branch to another within the same organization, optimizing inventory distribution. Conversely, Stock Transfer Inwards is the process feature where the receiving branch accepts the transferred stock initiated by the sending branch, ensuring efficient and coordinated inventory management.

- Stock Transfer Adjustments: Feature designed for making necessary adjustments to the existing stock, involving the addition and deletion of spare parts to align with the current available quantity. This ensures accuracy and optimization in managing inventory.

- Cycle Count: This feature functions as a process tool for adjusting stock levels during auditing, ensuring a systematic approach to maintain accuracy and align with the current inventory status.

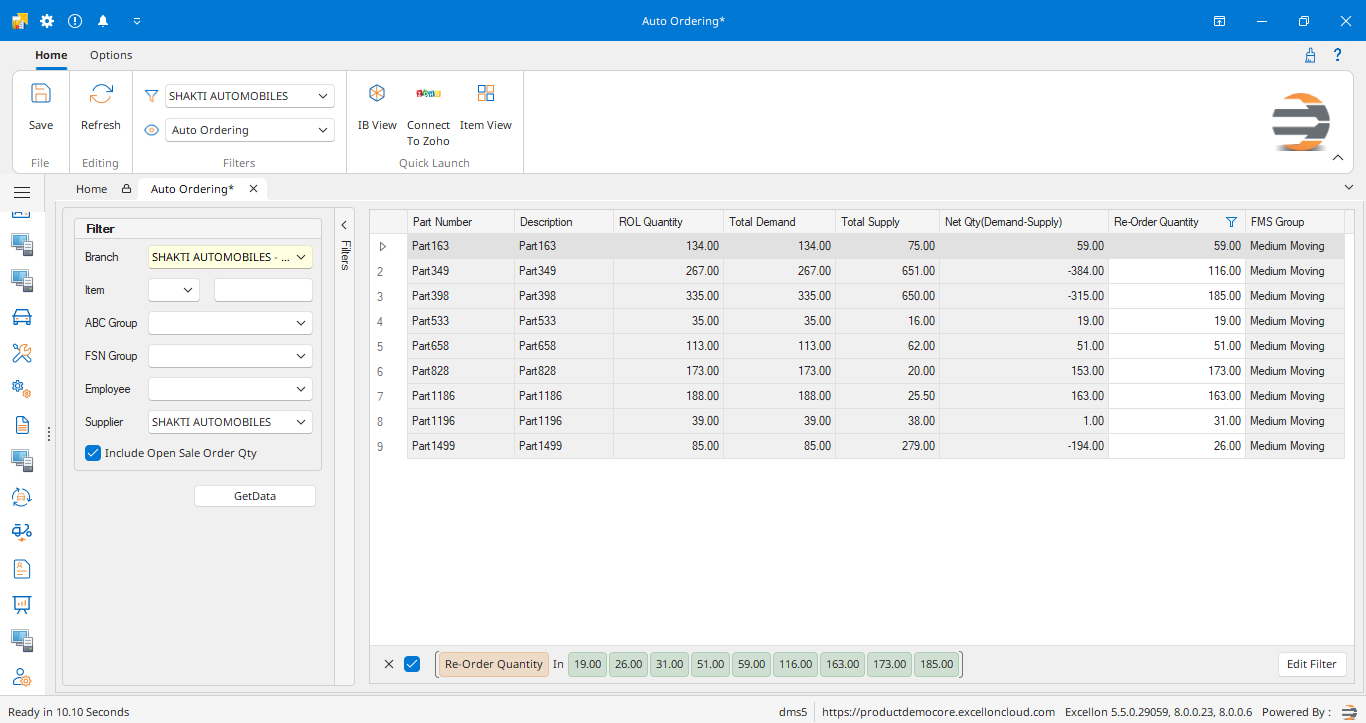

This process involves making predictions about demand, setting stock thresholds, and using data analysis to generate purchase orders automatically when inventory levels reach a certain point. By anticipating needs based on historical data and trends, this system ensures that restocking happens on time, reduces stockout occurrence and improves the supply chain’s overall efficiency. The outcome is an optimized approach to managing inventory that minimizes stock while meeting customer needs without incurring costs.

Special Features

Features in Detail

- Tracking of Returns: Track and manage the return of goods by recording the reason for the return, the date of return, and the quantity returned.

- Inventory Management: Automatically update inventory levels based on returned items, ensuring the business can accurately view its stock levels.

- Refund Processing: Refund process can be automated for returned items, including crediting the customer’s account and issuing credit notes.

- Supplier Management: Manage the communication with suppliers, including sending notifications of returns, tracking the status of returns, and providing detailed reports.

- Reports: Get detailed reports and analytics on returns, allowing businesses to identify trends and make data-driven decisions to improve their operations.

Implementing a purchase return management feature can help businesses to streamline their operations, reduce errors, and improve their customer service by providing a more efficient and effective way to manage returns.

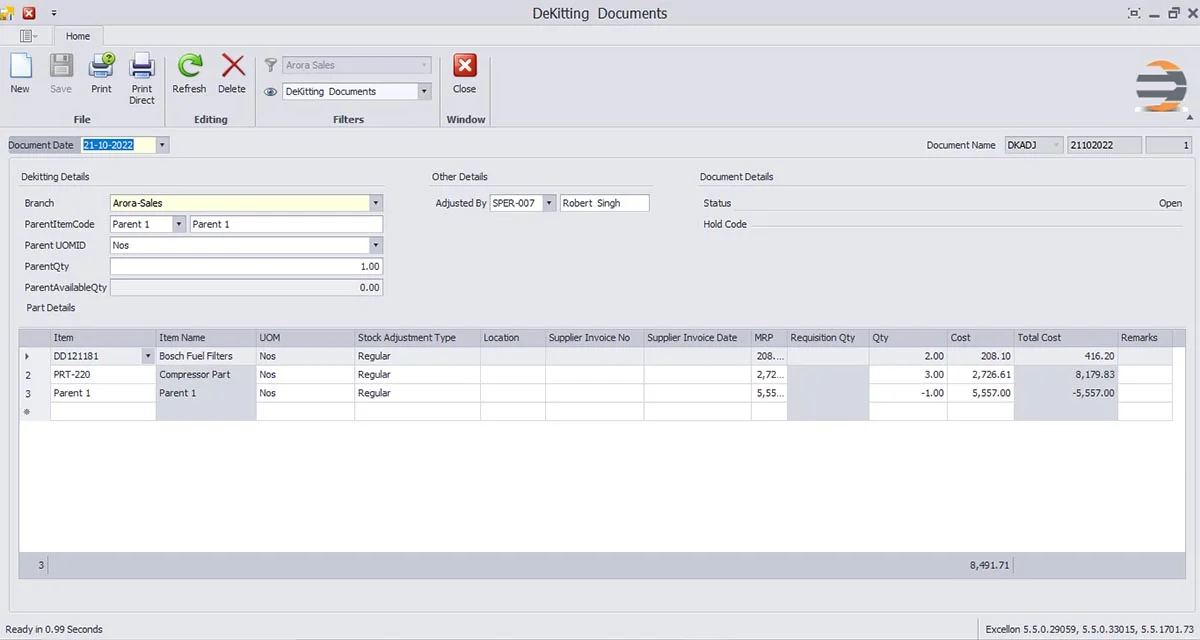

Kit De-kitting Document

A kit De-kitting document is a record that documents the process of assembling kits or breaking down kits into individual components within the automotive industry. When assembling kits of spare parts for specific purposes or when disassembling kits to use their components separately, this document provides a clear account of the items involved, their quantities, and their intended use. This practice ensures accurate tracking of parts, aids in inventory management, and supports efficient maintenance and repair operations.

Special Features

Features in Detail

- Inventory Accuracy: Maintain precise records of kit assembly and de-kitting actions, ensuring accurate stock levels.

- Efficient Maintenance: Support timely repairs by quickly identifying and accessing individual components.

- Optimized Inventory Usage: Enhance stock management by repurposing kit components for specific needs.

- Cost Savings: Minimize unnecessary purchases by utilizing components from existing kits.

- Traceability: Track the history and usage of kit components for better accountability.

- Streamlined Processes: Expedite maintenance tasks by having clear documentation of components.

- Resource Management: Efficiently allocate personnel and resources for assembling or de-kitting activities.

- Customer Satisfaction: Improve service turnaround time by swiftly accessing needed components.

- Preventive Maintenance: Facilitate scheduled maintenance by having the necessary components readily available.

- Data-Driven Decisions: Use data from kit de-kitting activities for informed inventory management strategies.